Offset printing process because it involves both physical and chemical content, for mastering the process and technology will have high requirements, often due to the management staff, operators of the process, technical level and other issues, resulting in more offset printing failure.

Offset printing characteristics

Offset printing is the use of oil and water repellent principle to print on the same printing plate. The graphic part is hydrophilic and hydrophobic, and the blank part is hydrophilic and oleophobic, which is the most obvious difference between offset printing and other printing, and is also the key to offset printing process technology.

In the printing plate layout at the same time the presence of ink and water, the transmission of ink on the ink roller contact with water, due to the high-speed rotation of the ink roller, under the action of mechanical force extrusion, the water mixed into the ink, resulting in ink emulsification, normal printing to a reasonable emulsification value. Therefore, offset printing actually uses both the principle of oil and water repulsion, and the characteristics of oil and water soluble emulsification.

(According to experimental information, offset printing can generally be printed normally, the reasonable emulsification value of the ink, water accounts for about 20 to 25%, no domestic instruments to determine, all by the operator's skills and experience to decide, which contains unstable factors, which also increases the possibility of failure.)

The water used in offset printing, not pure water, PVA version of the water contains phosphorus, chromic acid, the corrosion of the layout is very large, not only corrosive layout of the blank part of the sand, and constantly increase the organic salt layer, but also corrosive graphics part of the base paint, resulting in the printing plate to reduce the printing rate. PS version of the water with the addition of wetting powder contains more than ten chemical components, belonging to the slightly acidic wetting agent, with cleaning effect, the corrosiveness of the printing plate is minimal.

Printing pressure

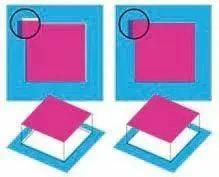

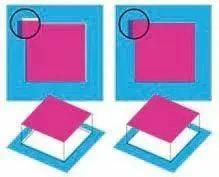

Printing pressure is also a major basis for the process technology. Offset printing because it is indirect printing, the image is transferred from the plate cylinder to the rubber blanket for the first impression, the rubber cylinder is inked, the impression is transferred to the substrate, which is the second impression, the pressure required for the two impressions is different.

(General offset printing machine, the pressure between the printing plate cylinder and the rubber cylinder, about 0.10mm; rubber cylinder and the pressure between the impression cylinder, about 0.20 ~ 0.25mm or so. With the better flatness of the PS version and the use of imported air cushion blanket, the pressure between the plate cylinder and the rubber cylinder can be smaller, such as imported Heidelberg four-color machine in 0.05mm can be printed.)

The pressure used in offset printing is achieved by calculating the radius of the cylinder, measuring the center distance, measuring and increasing or decreasing the number of pads. Offset printing pressure must be standardized, data control, do not arbitrarily increase the pad lining, blindly increase the pressure, resulting in sudden changes in pressure, the roller surface line speed is not equal, the contact surface friction increases, and even other failures such as greasy, heavy shadow, ink bar.

Therefore, the correct use and adjust the printing pressure, is an important part of the process technology required to print good products.

Overprint inaccuracy can be divided into two categories: vertical overprint inaccuracy and horizontal overprint inaccuracy. There is a statement that says "paper in the transmission process always has a machine firmly control, can ensure accurate overprinting." In fact, this statement is not comprehensive.

(For example, embossing bite shaft or sleeve wear, it can also be firmly controlled in the transfer of paper, but can not do the correct control. This is like a person holding a ball in two hands, two arms straight can hold firm, two arms bent can also hold firm, but two different positions holding the ball, leaving the body's distance, stability, etc. is not the same. Therefore, it should be said that "the correct firm control to ensure the accuracy of the set of printing".)

Causes of inaccurate overprinting many reasons, the common ones are: paper stretching, paper delivery crooked section, rules positioning inaccuracy, bite teeth bite force is not enough, bite teeth shaft wear, crossover does not meet the requirements, handing the paper teeth drive parts wear and so on.

In addition, some special factors can also cause the set is not allowed, such as the rubber blanket local deformation is large, can also make the image of the local overprint is not allowed; handing the paper tooth shaft, embossing cylinder shaft axial movement, will cause the horizontal overprint is not allowed.

Color sequence arrangement

Previous monochrome machine printing color sequence, always down the color sequence yellow, red, blue, ink, this color sequence arrangement, the greater difficulty is to sign the yellow version, red version of the printing sample, especially the first color yellow version, related to the color reproduction and reproduction effect of printed materials.

(If the yellow version is printed too deep, printed out of the character's skin color no sense of vitality, houses like ancient temples as old, making it difficult to accept; If the yellow version is printed too light, replicating the image of dry and no light, the tone is biased toward blue and purple, also not good.)

(Yellow version of the sign sample off-color, there are two main reasons: First, the human eye retinal color cells, the lowest ability to distinguish yellow; Second, people do not know much about the oil absorption of paper, the lack of instruments to detect, the size of the same mastery, often resulting in too deep, too light malady.)

Two-color machine color sequence arrangement can be yellow and blue version of the same printing process, the blue version just play the role of blue glass color filtering, to facilitate the identification of the yellow version of the ink layer thickness is appropriate. But two-color machine because it is wet stacking wet printing, often in the dragging tip of the two corners of the irregular A, B reshading, which requires the process arrangements, appropriate changes in the color sequence to solve.

More than four-color multi-color offset printing machine, due to three colors is wet stacking wet printing, so the color sequence is based on the viscosity of each color ink, from high to low arrangement, otherwise reverse overprinting failure will occur, resulting in ink gray mixed color malady. Sometimes the first few colors will also produce A, B overlap, color sequence to make the necessary adjustments.