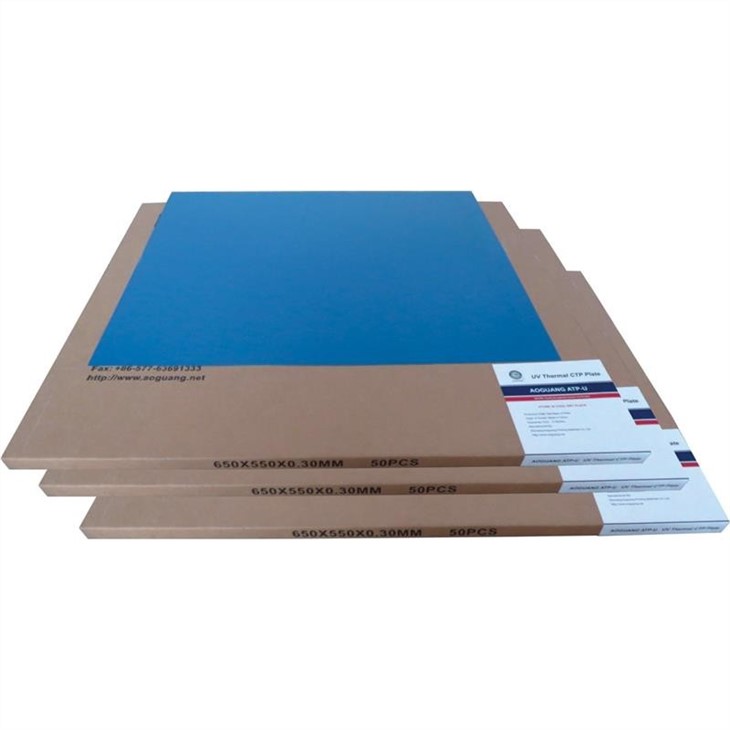

UV CTP PLATE

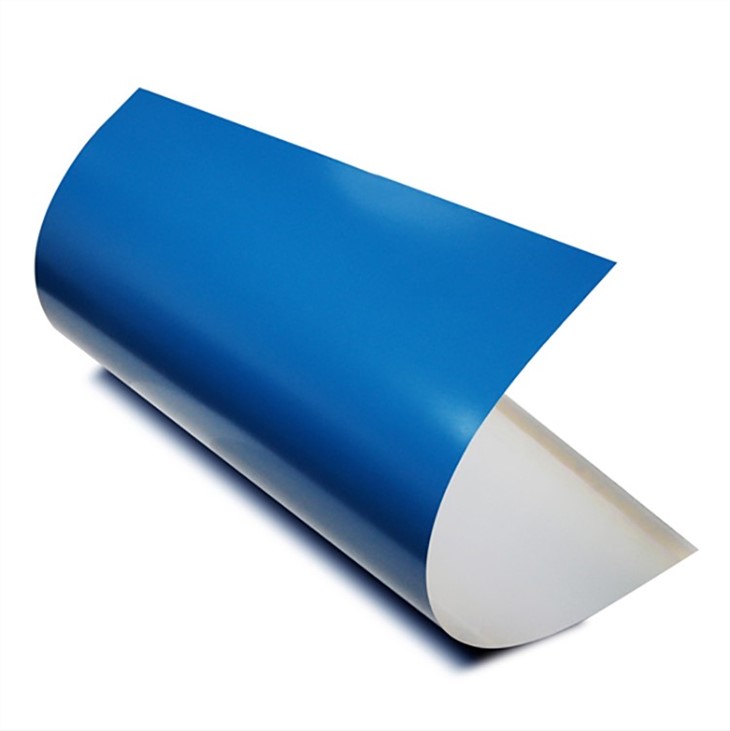

High quality uv-ctp plate for printing customers, so that printing enterprises in ensuring production efficiency while giving consideration to economic benefits, can be widely used in commercial sheeting and rotary printing.This plate is specially designed for CTCP technology, using a new uv coating formula and high quality electrolytic oxidation treatment of aluminum plate base.Uv-ctp S uv-ctp is a double layer uv-ctp specially developed for high-end customers, it has a higher sensitivity, longer printing process, and can be used for UV ink printing.

SPECIFICATION

Type: Positive UV-CTPPlates, S Type double

Spectral Sensitively: 400-410nm

Exposure Energy: 40-50mj/cm2

Developing Time: 20-30 seconds (STRONG Solution :water=1:4,23±2℃

Resolution: 2~98%

Run-Length: 100000-2000000(Normal ink ,unbaked)

50000-100000(UV ink)

*Run-Length varies with its printing conditions and imaging content

Safelight: Yellow light

Positive PS PLATE ADVANTAGES

1. Excellent printing performance: the new exposure layer formula and high-quality plate base treatment technology enable the plate material to have precise dot reduction, excellent ink balance performance and superior wear resistance, and its non-roasting plate printing resistance can reach more than 150,000, which can be applied to UV ink printing after roasting.

2. High quality imaging performance: this edition has a high resolution, achieving 2 to 98% of @250lpi am screening resolution and 25 micron FM screening resolution.

3. Good stability and adaptability: good storage stability, in the shelf life of its sensitivity, dot reduction and other performance changes are small.Suitable for the mainstream of the market uv-ctp plate making equipment, the development of good adaptability, offset packaging and commercial printing is the best choice.