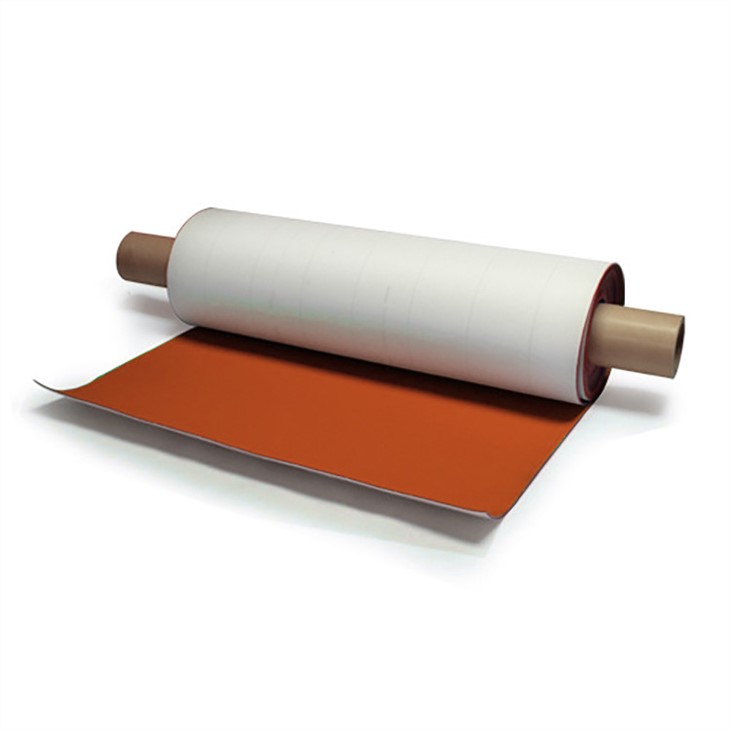

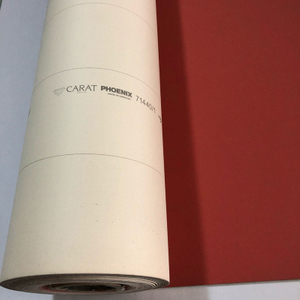

UV Printing Blanket

Printing blanket unique high pressure microsphere air cushion technology, making blanket more pressure resistant, reducing stronger; Strong stretch cloth base reduces the deformation of the blanket to the minimum, maintaining the stability of the thickness, so that the printing pressure is balanced; The rubber surface with fine polishing of special material makes the ink transfer more fully, the substrate stripping more easily, the dot gets sharp reproduction, the field is flat without ink, the printing quality gets the best play.

Number of floors: 2 floors (type 2000), 3 floors (type 3000), 4-5 floors (type 5000)

Thickness specification: 1.70mm and 1.97mm

Width specification: 520mm-680mm-780mm-960mm-1060mm-1350mm-1480mm

Package length: 25-30 meters

Color: pink

Speciality

1. Stable field printing quality for a long time.

2. Different types of paper printing paper mark busters.

3. Especially for thick paper with excellent absorption bar.

4. Not easy to produce the end of the plate mark and has good durability.

5. Good reproducibility and easy absorption of striations.

6. Easy to clean.

Technical Parameters

Tensile strength: > 4000 N

Extension: < 1% (1000N/50mm load)

Hardness: 80 IRHD

Microhardness: 68 IRHD

Compressibility: 60 mJ (on the 5th compression cycle)

Surface roughness: 0, 8-1,0 m Ra

Use blanket cleaner for swelling: < 1%

Use blanket reducer: 5-6%

Use MEK 22 %

Maintenance

Blanket replacement is due to abnormal factors caused by the reasons. (That is: small area can not change a large area, not resistant to cleaning and very paper folding Angle, double sheet, pulp block)

It is suggested that you can do the following:

Continuous printing of 12 pieces of paper, that can automatically restore, or stop machine to replace the lining or gun bottom paper, and then print 22 pieces of paper to restore, and other brands generally in 0.20 m0. About 30mm, if the problem still appears, please adjust the use according to your experience.

Clean

We recommend that users use the following steps to clean the blanket:

1. Use warm water to wipe away water-soluble substances such as paper powder.

2. Use no damage to the blanket car wash water or solvent wipe ink and other solvents dissolved in the material.

3. Such as rubber city surface calcium magnesium ion deposition can choose to contain citric acid car wash water or weak acid such as vinegar for cleaning.